MEAT & POULTRY

CMP offers a wide range of hygienic processing equipment for meat and poultry. We have extensive experience in all areas of today’s modern meat and poultry plant including slaughter, processing, and packaging areas. Our solutions are often coupled with FPS spiral and tunnel freezers, including turn-key controls and automation. We incorporate equipment from other leading OEM’s to offer complete processing lines.

We offer hygienic process decks, boning and cut tables, sanitary conveyors, hygienic tote dumpers, washers, scale decks, continuous fresh water chillers and brine freezers for meat products, whole birds, offal and giblets.

CMP can provide sound technical advice, project management services, and hygienic processing equipment to meet the needs and specifications of our customers.

CASE STUDY

CASE STUDY

End-to-End Solutions:

Poultry Infeed System to

FPS Spiral Freezer

Challenge

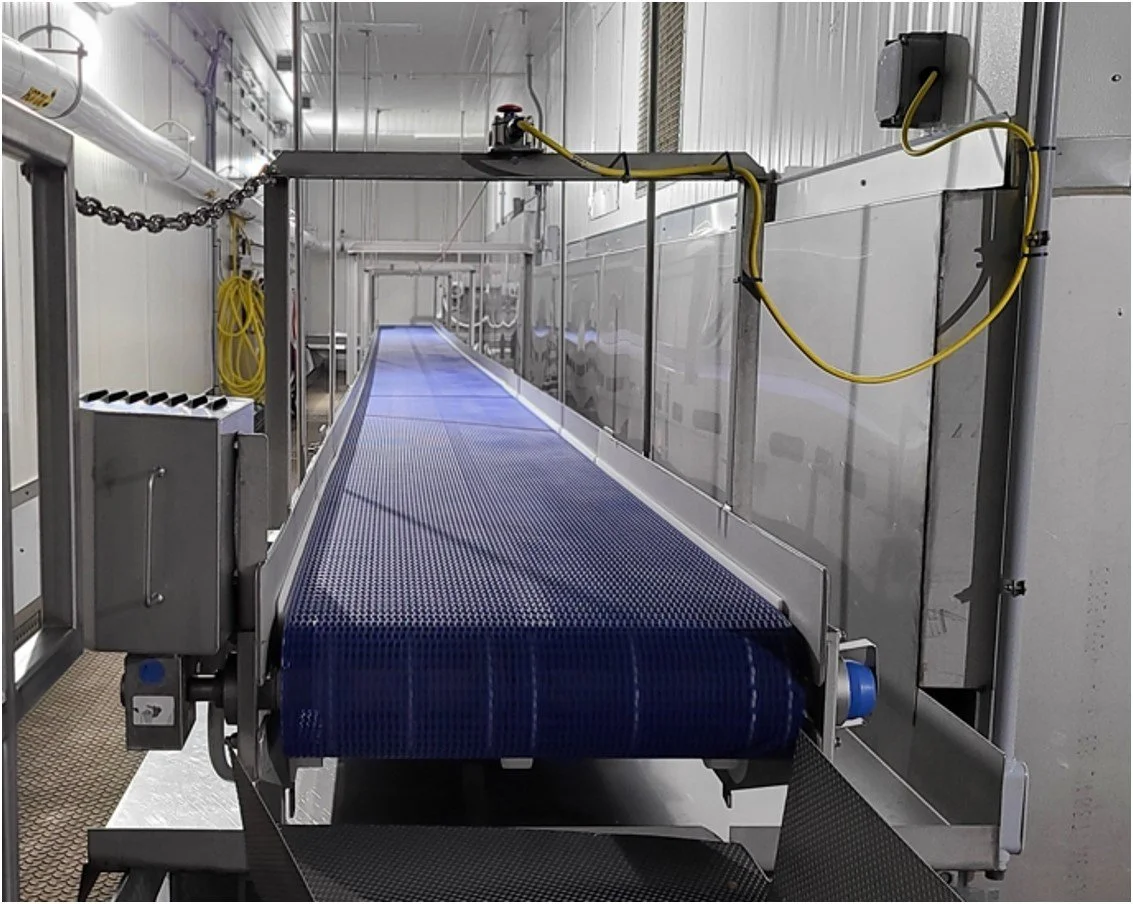

1/ Require an integrated spiral freezer feed system from injector/massager to the spiral freezer

2/ Maximize throughput and use of entire spiral belt width with excellent product quality

Solution

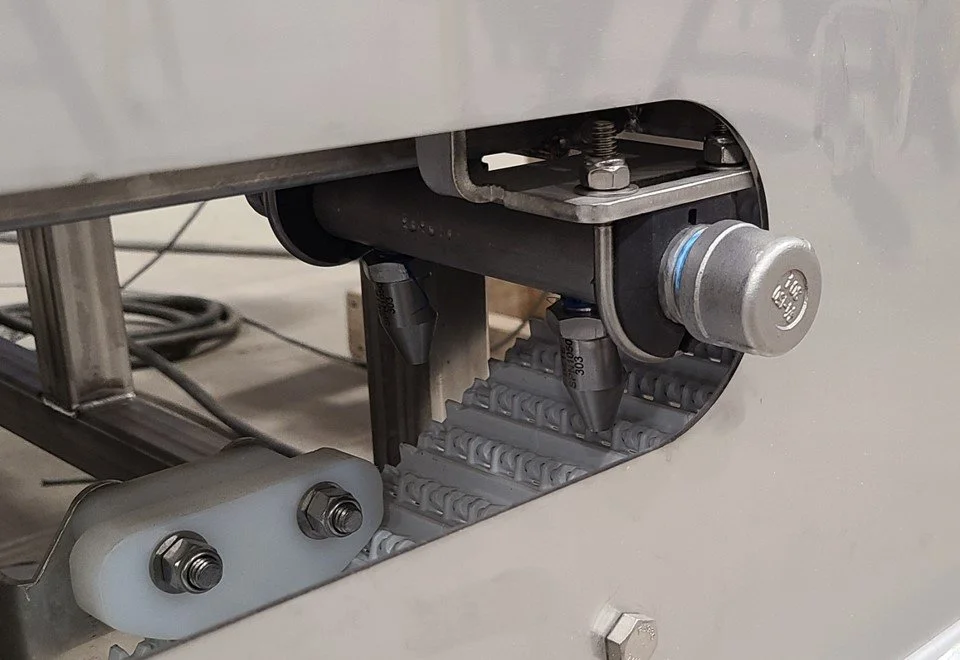

1/ Hygienic conveyors, metering hopper, styling belts, tight nose transfer, adjustable ergonomic work platforms

2/ Controls integrated with FPS spiral freezer controls for seamless rate setting

Result

Fully integrated solution allowed for maximum throughput target of 1800 kg/hr. to be achieved by maximizing available belt area

CASE STUDY

Hygienic Conveyors:

Multi-station Trim Conveyor

for Raw Poultry

Challenge

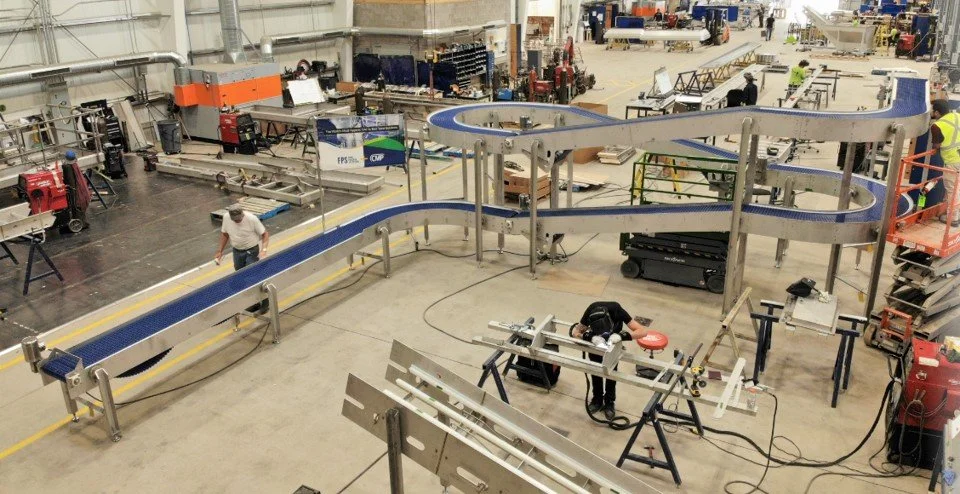

Canadian poultry processor looking for a sanitary trim station for trimming raw chicken breast. Needed turnkey system complete with 28 workstations, trim take-away conveyors, and bi-directional center conveyors. Customer wanted to raise their sanitary standards in the plant.

Solution

CMP Multi Station Trim Conveyor complete with (28) workstations, identical and reversible. 6 sanitary conveyors built into 1 frame complete with SS drum drives for center bi-directional conveyors. SS control panel complete with HMI touchscreen and pull-cord safety STOP.

Result

System fully tested in-house with product and at maximum rate. Conveyors operate smoothly and consistently. CIP headers included for hard-to-reach areas. Customer ordered additional equipment for a different area of the plant. Another successful project with a new customer!

CASE STUDY

Hygienic Conveyors:

Walk-overs

for Operator Egress

Challenge

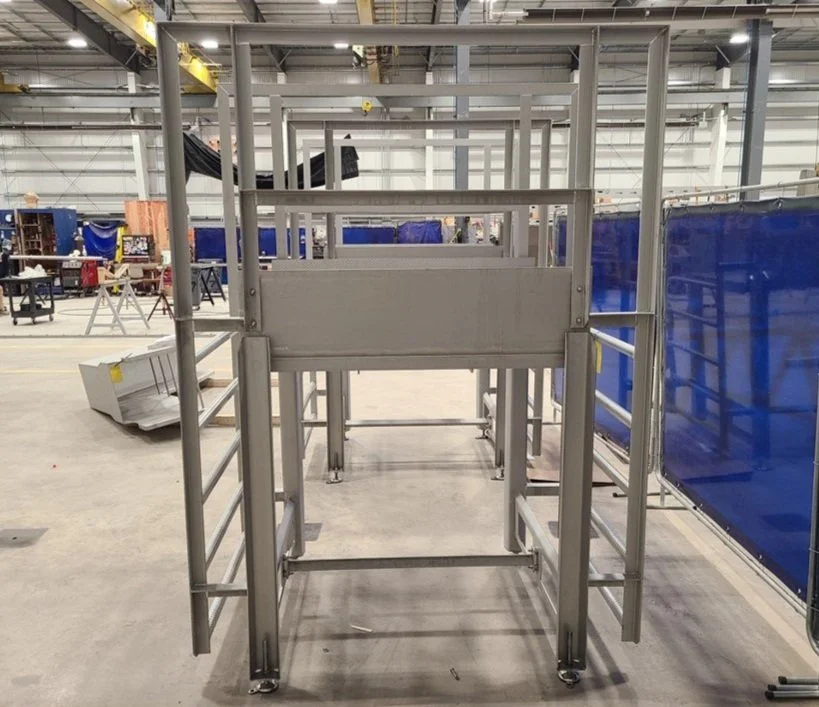

Beef processing customer needed a solution for their operator egress. Customer not interested in complicated gates, looking for a simple, sanitary solution for crossing over conveyors with open product on them.

Solution

Hygienic Conveyor Walk-overs complete with formed SS anti-slip plate to ensure no dirt, dust, or water can drip onto the conveyor and product below. Heavy-duty construction complete with no hollow materials. Food grade fit and finish.

Result

Customer ordered six (6) complete units with anti-slip ladder on both sides. Walk-overs designed and built for a harsh environment, heavy-duty frames, material thickness, and cross bracing. CMP Project managers worked with onsite installers to ensure easy and efficient installation.

CASE STUDY

Thermal Solutions:

Whole Bird

Chiller System

Challenge

1/ Large US based poultry processor looking for turnkey solution for chilling their wrapped whole birds.

2/ Current process is manually adding ammonia chips to cases to chill the birds. This process is costly and ineffective for the rate of 40ppm, 14,400 lbs./hr.

Solution

CMP turnkey Brine Chiller system that maintains location of existing equipment and effectively chills the birds from 45F to 28F using the plant space available. Solution included brine dosing, the ammonia to glycol chiller, and all controls.

Result

1/ Complete turnkey project including FAT, delivery, installation, and commissioning.

2/ The new chilling system has transformed how this customer operates their production.

3/ USDA approval for the new system and better than expected production rate increases.

CASE STUDY

Tote Handling Systems:

Sanitary

Tote Tipper

Challenge

Large meat processor in Canada needed to safely and easily tip their clean plastic totes to remove any residual water from the tote and allow an operator to easily rinse out the tote while it is in the tipped position. Aiming for a small footprint because this unit will be installed in a busy shipping area.

Solution

Light-duty tote tipping unit that is simple to maintain and economical. No hydraulics or pneumatics are required. A simple electric motor and gear reducer rotate the tote in a safe and controlled manner. SS mesh perimeter cage with safety interlocked tote gates and operator gate.

Result

The final solution passed stringent facility safety standards. The integrated control panel is easy to operate. All construction and components are robust and rated for a full washdown environment. Operators can now safely tip and rinse totes without straining themselves leading to increased food safety.

CASE STUDY

End-to-End Solutions:

Chicken Nuggets Transfer

from FPS Spiral Freezer

Challenge

Require an integrated spiral freezer feed and discharge system for two FPS spiral freezers including spiral decline chute, glaze conveyor, and transfer conveyors.

Solution

1/ Hygienic conveyors, metering hopper, styling belts, tight nose transfer, adjustable ergonomic work platforms.

2/ Controls integrated with FPS spiral freezer controls for seamless rate setting.

Result

1/ Fully integrated solution allowed for maximum throughput target of 1800 kg/hr. to be achieved.

2/ Customer expectations exceeded. Conveyors are easy to clean and reliable. Turnkey approach appreciated and valued by the customer.

CASE STUDY

End-to-End Solutions:

Case Handling from

Carton Freezer

Challenge

Decline full boxes discharged from CF at -35F from 127” exit height to floor level for manual palletizing. With floor area constraints, customer wanted simple, traditional solution.

Solution

Incorporate a combination of radius and straight decline conveyors to achieve controlled decline of cases. Heavy duty design and build using SS plate sides to handle heavy case loading.

Result

System tested in-house using fully loaded, maximum weight, customer cases. Case run smoothly and consistently. Customer ordered installation and commissioning as an additional order.

CASE STUDY

End-to-End Solutions:

Beef Processing

Plant

Challenge

Largest meat processing enterprise in the world building a state-of-the-art beef processing plant designed for 420 head/hour. Looking for an experienced food industry supplier with the highest level of hygienic equipment.

Solution

1/ 185’ long, Heavy-duty SS Viscera Table Conveyor

2/ QTY 60, SS Sanitary Operator Platforms and Machine Decks

3/ QTY 100, SS Heavy-duty Sanitary Conveyors

4/ Complete Tripe Wash and Processing Area System

5/ Complete Petfood Processing System

Result

This processing facility has become the show-piece plant for this customer. All equipment was expertly installed and has set the industry standard for beef processing in the US. Multiple repeat orders for CMP from this happy customer.